Time:2024-08-16

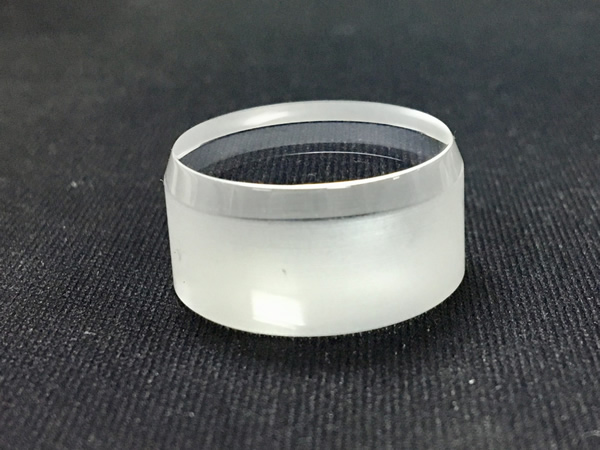

In the field of manufacturing and maintenance of precision optical instruments, every subtle operation may directly affect the performance and quality of the product. Among them, as the core component of optical systems, the cleanliness and protection of optical components are even more crucial. Therefore, the principle that "dust-free gloves or finger cots should be worn when using optical components, and direct contact with the surface of the lens is prohibited" is not only a consensus in the industry, but also the cornerstone of ensuring the accuracy and lifespan of optical instruments. The following will explore the scientific principles, practical significance, and specific applications behind this principle in practical operations.

1、 Principles of Science

Optical components require high surface smoothness, and any tiny dust, oil stains, or fingerprint residue can become a source of light scattering, affecting the efficiency of light transmission and imaging quality. Dust particles can scatter incident light, resulting in blurry images; Oil stains and oils in fingerprints may alter the refractive index of the lens surface, further exacerbating imaging distortion. In addition, direct contact may also introduce static electricity, adsorb more particles in the air, and form a vicious cycle. Therefore, maintaining the cleanliness of the lens surface is the key to ensuring stable performance of the optical system.

2、 Practical significance

1. Improving imaging quality: Following this principle can effectively reduce surface contamination of the lens, ensure accurate propagation of light along the designed path, and thus enhance the clarity and contrast of the image.

2. Extending service life: Reducing physical contact and pollution means reducing the risk of lens surface wear and chemical corrosion, which helps to extend the service life of optical components.

3. Improving work efficiency: Although regular cleaning and maintenance are time-consuming, they undoubtedly significantly improve work efficiency compared to frequent adjustments or replacements required due to performance degradation caused by lens contamination.

4. Ensuring research and production accuracy: In high-precision fields such as scientific research, medical, aerospace, etc., the cleanliness of optical components directly affects the accuracy of experimental results and the reliability of products.

3、 Specific applications

1. Preparation before operation

① Wear dust-free equipment: Before performing any operation related to optical components, operators should wear specialized dust-free clothing, dust-free hats, dust-free shoes, and dust-free gloves or finger cots to ensure that there are no exposed parts of the body that may cause contamination.

② Environmental control: The operating area should maintain a constant temperature and humidity, and be equipped with an efficient air filtration system to reduce dust particles in the air.

③ Preparation of tools and materials: Use specialized cleaning cloths, cotton swabs, dust-free paper, and suitable cleaning agents, and avoid using items containing abrasive particles or corrosive components.

2. Precautions during operation

① Handle with care: When handling and installing optical components, special fixtures or gloves should be used to avoid direct contact with the surface of the lens by hand.

② Avoid touching: When adjusting or inspecting components, try to operate through edges or brackets to avoid direct contact between fingers or tools and the lens.

③ Regular cleaning: Develop a reasonable cleaning plan based on usage frequency and environmental conditions, use the correct cleaning methods and materials, and ensure that the surface of the lens is always kept clean.

3. Special case handling

① Accidental contamination: If pollutants accidentally splash onto the lens, the operation should be stopped immediately and appropriate cleaning agents and methods should be used to remove them, avoiding secondary damage caused by excessive force or improper cleaning tools.

② Damage assessment: For damaged lenses, a detailed assessment should be conducted to determine whether it affects performance, and replacement or repair should be carried out if necessary.

The principle that "dust-free gloves or finger cots should be worn when using optical components, and direct contact with the surface of the lens is prohibited" is an indispensable part of optical instrument manufacturing and maintenance. It is not only an important measure to ensure the stability of optical system performance and extend its service life, but also the key to improving work efficiency and ensuring scientific research and production accuracy.

Tel

Mobile phone

Customer service

TOP