Time:2025-03-07

Sapphire lenses occupy an important position in the field of optical products due to their hardness, transparency, and wear resistance. From wristwatches to precision camera lenses, their unique performance has become a choice for many products. This article will provide a detailed analysis of the manufacturing process of sapphire lenses, leading you to understand this complex and intricate craftsmanship.

1、 Raw material preparation

The chemical formula of sapphire is Al ? O ∝, which is a single crystal of aluminum oxide. The raw material for manufacturing sapphire lenses is usually high-quality alumina powder, which requires strict screening and testing to ensure its high purity, complete crystal structure, and absence of cracks and impurities. In addition to alumina powder, oxygen and hydrogen are also required as auxiliary gases during the manufacturing process, as well as various tools and materials for cutting, grinding, and polishing.

2、 Crystal growth

The growth of sapphire crystals is a key step in manufacturing lenses, and commonly used crystal growth methods include pulling and bubble forming. The pulling method involves adding a corresponding amount of solvent to the molten alumina to achieve supersaturation, resulting in the precipitation of sapphire crystals on the seed crystal. This method can grow high-quality sapphire single crystals, but it requires strict control of parameters such as temperature, concentration, and pulling speed. Crystals grown by the Czochralski method have high uniformity and good optical properties, making them materials for manufacturing lenses.

The bubble growth method is to grow sapphire crystals on the seed crystal by vapor deposition under high temperature and high pressure. This method has a fast growth rate and can produce large-sized sapphire crystals, but the crystal quality may be slightly inferior to the Czochralski method. The bubble generation method is suitable for situations where there are high requirements for crystal size but relatively low requirements for optical performance.

3、 Cutting and Grinding

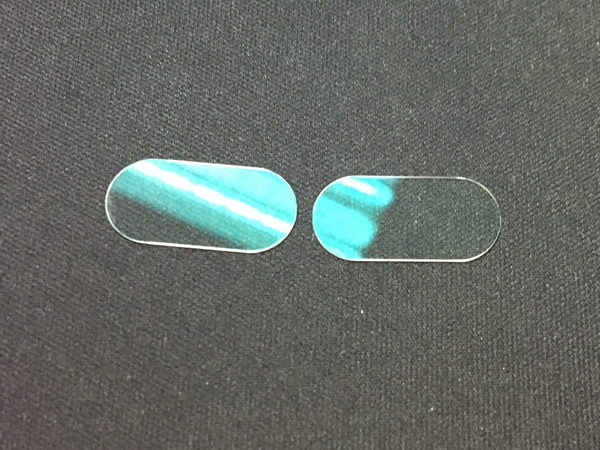

The sapphire crystals grown need to undergo processing steps such as cutting, grinding, and polishing to prepare lenses that meet the requirements.

Cutting is the process of cutting sapphire crystals into the desired shape and size, which requires high-precision cutting equipment and skilled operating techniques to ensure cutting accuracy and surface quality. During the cutting process, it is necessary to use diamond blades or laser cutting machines for precise cutting to obtain lens blanks with regular shapes and accurate dimensions.

Grinding is used to remove burrs and unevenness generated during the cutting process, making the surface of sapphire crystals smoother. During the grinding process, it is necessary to choose appropriate grinding materials and techniques to avoid damage to the sapphire crystal. Usually, the grinding process is divided into three stages: coarse grinding, medium grinding, and fine grinding, gradually removing surface defects and unevenness.

4、 Polishing and Cleaning

Polishing is an important step in achieving high smoothness and transparency on the surface of sapphire lenses. During the polishing process, specialized polishing machines and polishing solutions are required, and polishing time and pressure parameters are strictly controlled. The polished surface of the lens should be as smooth as a mirror, without obvious scratches or defects.

After polishing, the lens needs to be cleaned. During the cleaning process, it is necessary to use an ultrasonic cleaning machine to perform high-frequency vibration cleaning on the lens to remove small particles and stains on the surface. Ultrasonic cleaning has the advantages of high efficiency, speed, and no pollution, making it an ideal choice for lens cleaning.

5、 Physical reinforcement

In order to improve the impact resistance and wear resistance of sapphire lenses, physical strengthening treatment is required. The principle of physical strengthening is to heat sapphire lenses to a certain temperature, so that the internal stress inside the lens is eliminated, and then quickly cool, causing compressive stress on the surface of the lens, thereby improving the strength and hardness of the lens.

During the physical strengthening process, the lens needs to be sent into a physical strengthening furnace for heating and cooling treatment. The heating temperature and time need to be strictly controlled to ensure uniform distribution and elimination of internal stress in the lens. The cooling process usually uses air cooling to rapidly cool the lens and generate compressive stress.

6、 Coating treatment

Coating is used to improve the performance and service life of sapphire lenses, and commonly used coating materials include silicon dioxide, silicon nitride, titanium oxide, etc. After coating, the lens has better scratch resistance, wear resistance, and pollution resistance, while also improving its optical performance.

During the coating process, the lens needs to be placed in the coating machine with the inner surface tightly attached to the tray. Then seal the coating machine and vacuum it to a high vacuum state. Then, the coating material is electrically heated to evaporate and deposit on the surface of the lens, forming a nanoscale thin film. The coating process requires strict control of parameters such as temperature, pressure, and concentration of coating materials to ensure the quality and uniformity of the coating.

7、 Testing and Quality Control

After manufacturing, strict testing and quality control are required for sapphire lenses. The testing items include indicators such as transmittance, refractive index, hardness, wear resistance, etc. Common testing methods include spectrophotometry, ellipsometer, microhardness tester, etc.

Transmittance detection can evaluate the transmittance performance of lenses; Refractive index detection can understand the optical properties of lenses; Hardness and wear resistance testing can evaluate the anti damage ability of lenses. Through these tests, we can ensure that the quality of the lenses meets the usage requirements and provide customers with reliable assurance.

The manufacturing process of sapphire lenses is a complex and intricate process that requires strict control over the parameters and quality of each link. High quality sapphire crystals are grown by pulling or bubble forming methods, and after cutting, grinding, polishing, cleaning, physical strengthening, coating treatment, and other steps, sapphire lenses with high transparency, hardness, and wear resistance are obtained. These lenses play an important role in the field of optical products due to their performance, bringing more convenience and beauty to life and work.

藍(lán)寶石火焰探測(cè)器圖片.jpg)

Tel

Mobile phone

Customer service

TOP